The Society of Manufacturing Engineers’ (SME) 2018 Annual Report took a deep dive look at medical additive manufacturing, more commonly referred to as 3D printing.

The organization sees significant growth for 3D printing industry noting a 21 percent compound annual growth rate in 2017 for an overall 3D printing market size of $7.3 billion with 11 percent of that coming from the medical and dental segment.

The report suggests that 3D printing applications driving the growth in the medical segment fall into seven general categories, including:

- Non-personalized instruments and prototypes

- Anatomical modeling

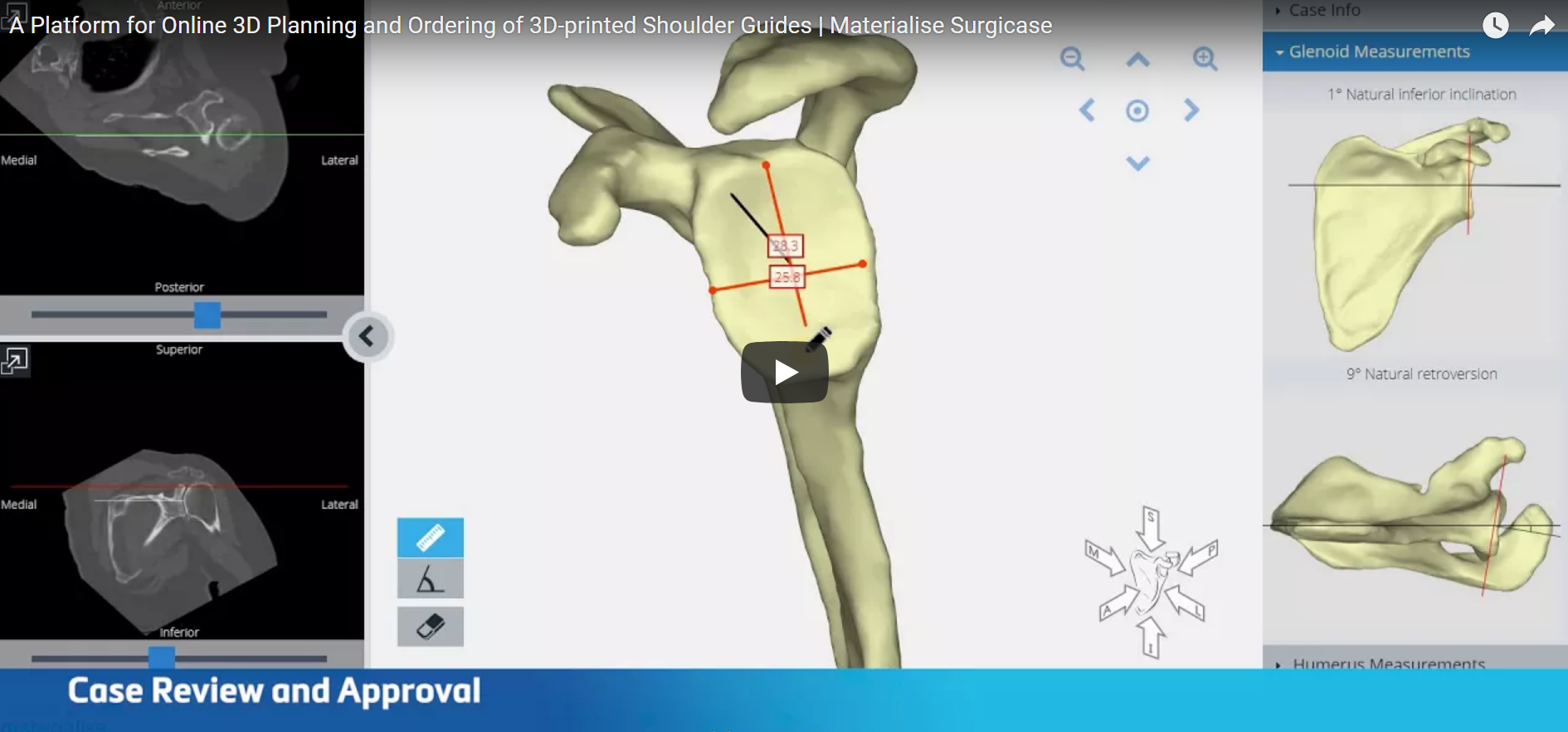

- Surgical planning

- Precision prosthetics

- Permanent implants

- Wearable devices

- Bioprinting tissues and scaffolds for regeneration, drug delivery/discovery, organ on a chip

Five of those categories: anatomical modeling, surgical planning, precision prosthetics, permanent implants, and bioprinting tissues, require tight collaboration among clinicians, engineers, and technicians, and such patient-specific manufacturing is driving the introduction of point-of-care (POC) hospital-based centralized 3D printing departments.

While POC manufacturing increased by 3200 percent between 2010 and 2017, the total number of in-hospital centralized 3D printing departments remains less than 100 and those are limited to larger academic and research institutions. Nevertheless, the benefits of POC manufacturing including quicker turnaround, team collaboration, and onsite quality control, is expected to fuel continued growth in medical 3D printing.

An alternative to developing an in-house 3D printing facility for smaller hospitals and medical device companies is the rise of full-service 3D contract printing companies that offer a variety of medical applications to leverage the advantages of 3D printing for treatment options and product planning and product development for device makers.

These companies offer medical providers and small device makers the ability to 3D print the surgical model or prototype they need without having to go through all the time, expense and regulatory headaches of tooling up and developing the in-house staff with the experience and technical skills needed to have a fully functioning 3D printing operation.

While there are a number of companies that provide a range of services supporting medical 3D printing, a few are even beginning to offer more extensive support for patient-specific manufacturing. For clinical providers, these companies offer support for multi-discipline patient-specific 3D printing treatment options, image-based planning and data conversion for 3D printing patient-specific implants, guides, as well as provide virtual planning services for surgery.

For small developers, these companies support 3D design and testing of new devices on thousands of virtual patients and assist in creating representative physical test models, which reduces design iterations and cadaveric and patient testing, with extensive data capture to support marketing and regulatory claims.

Outsourcing such full-service contract 3D printing support will form an important resource for hospitals, providers, and developers who do not have the resources in-house to take advantage of the benefits of 3D printing and will accelerate the growth of medical 3D printing.

Kapstone Medical is a full-service product realization firm that partners with inventors and manufacturers of all sizes to help them rapidly develop and commercialize new medical devices or processes, whether by assisting with in-house development, or connecting you with the best out-source fit for your needs. Visit our website or Call Us Today to learn more! Phone: (704) 843-7852 – email: info@kapstonemedical.com

Sources: SME 2018 Annual Report: Medical Additive Manufacturing/3D printing, and Materialise website.