Brief roundup of medical grade 3D printing materials

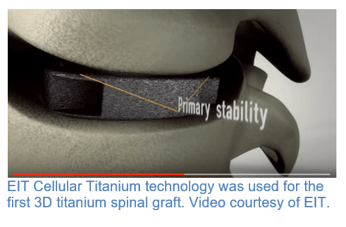

Following the first successful implant of 3D printed titanium cervical spine graft, announced last year at the German Society of Neurosurgery annual meeting, surgeon Uwe Spetzger pointed to the potential for using surgical implants that are not just tailored for a particular patient, but actually manufactured specifically for that patient.

“We are fascinated by the possibilities of this new technology combining modern computer-aided design and custom-made manufacturing of a high-tech cervical implant,” Spetzger said in a press release. “The future of patient individualized spinal implants has begun.”

In the last few years, rapid advances 3D printing technology, direct metal printing and emerging ceramic and biologic printing materials have accelerated a widening range of innovation and invention in 3D printed medical devices that promise to produce patient-matched surgical implants.

Titanium

EIT Emerging Implant Technologies GmbH, Germany, designed the implant Spetzger used for a patient with degenerative cervical spine condition. EIT is a newly formed company dedicated to developing 3D printed implant solutions, partnering with 3D Systems of South Carolina, the team used selective laser melting to manufacture a titanium implant with a porous surface that allows for natural bone ingrowth without the need to add bone graft. The individualization of the design provided a perfect match and exact fit to the patient’s individual anatomy.

Ceramics

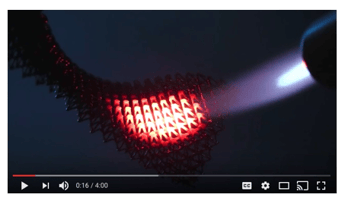

HRL Laboratories of Malibu, Calif. announced in the journal Science that it had invented a ceramic resin for 3D  printing, which after printing can be fired to produce a fully dense ceramic part. The resin formulation can be 3D printed into parts of virtually any shape and size. Firing converts the material into a high strength, fully dense ceramic with no shrinkage. The resulting material exhibits strength ten times higher than similar materials. Applications for ceramic implants range from dentistry to joint bearings in total joint arthroplasty. HRL is currently looking for a commercialization partner for this technology.

printing, which after printing can be fired to produce a fully dense ceramic part. The resin formulation can be 3D printed into parts of virtually any shape and size. Firing converts the material into a high strength, fully dense ceramic with no shrinkage. The resulting material exhibits strength ten times higher than similar materials. Applications for ceramic implants range from dentistry to joint bearings in total joint arthroplasty. HRL is currently looking for a commercialization partner for this technology.

Biomaterials

University of Toronto professor emeritus Bob Pilliar collaborating with a young mechatronics engineer, Mihaela  Vlasea at the University of Waterloo told the Toronto Star earlier this year that they have developed an additive manufacturing process using the main component of bone, calcium polyphosphate.

Vlasea at the University of Waterloo told the Toronto Star earlier this year that they have developed an additive manufacturing process using the main component of bone, calcium polyphosphate.

Their custom-built 3D printer uses ultraviolet light to bind the calcium phosphate powder together to design porous implants for a specific patient. The precisely arranged pores on the surface enables natural bone to grow inside the implant at different rates. Over time, the calcium polyphosphate is absorbed within the body while the patient’s own tissues and cells retain the artificial implant’s shape. The material is currently undergoing animal trials.

We partner with physician inventors and manufacturers of all sizes to rapidly develop and commercialize new medical devices. Visit our website at www.kapstonemedical.com contact us by phone (704) 843-7852 or email us directly at info@kapstonemedical.com.